ORiN is an active solution in various areas

Reducing the burden of connectivity to speed up problem-solving in every field of production

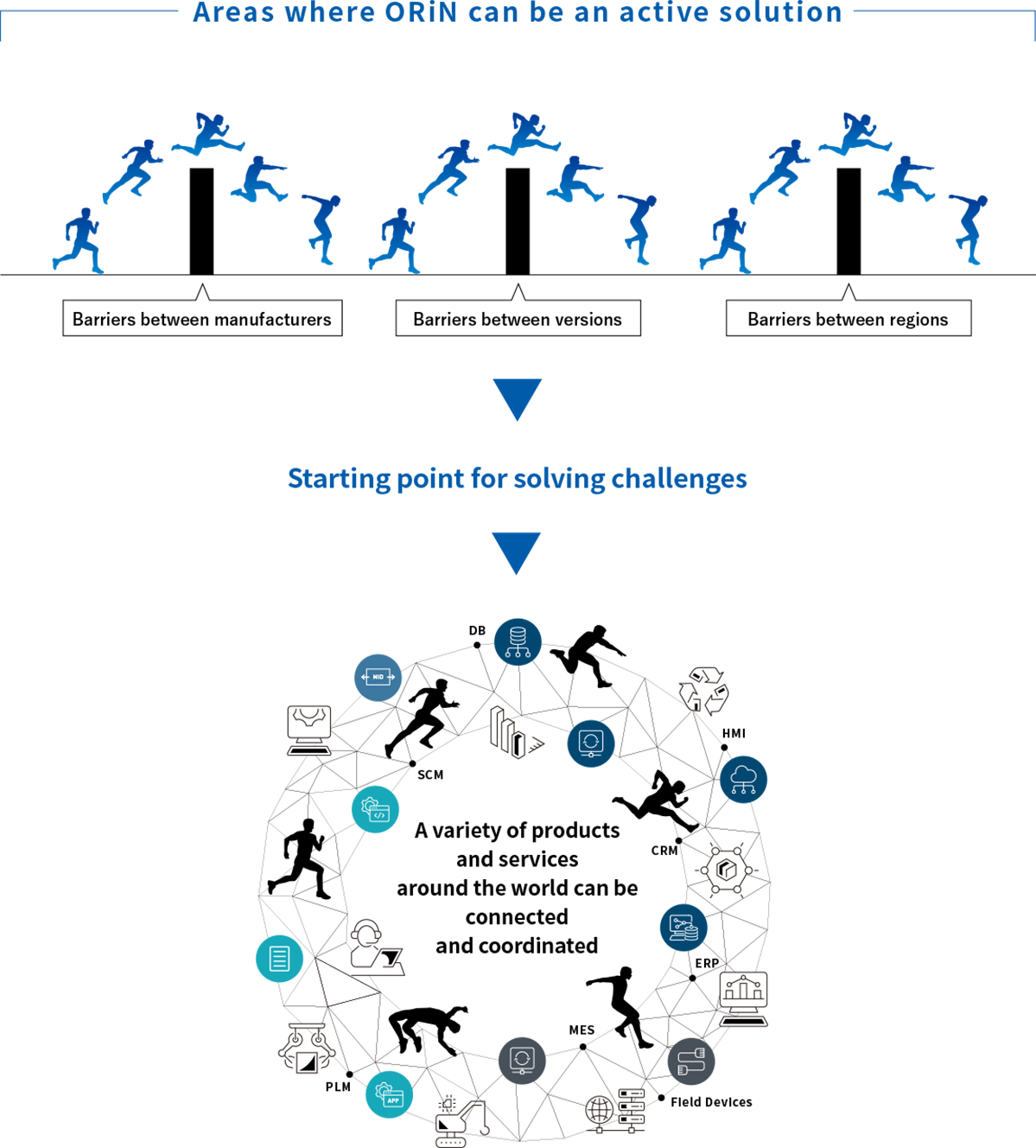

The connection of facilities with different standards can be very difficult and often becomes a barrier to the introduction of IoT into facilities.

ORiN, which can substantially reduce the burden of connection, allows you to identify challenges based on the extracted data and steadily introduce IoT through specific actions.

ORiN can help solve challenges involving connecting data in every production field, such as improving productivity through the coordination of systems in different factories, overseas transfer of facilities and continued use of older facilities.

As well as in the manufacturing industry, ORiN can be an active solution in various other areas such as primary industries and medicine.

The range of areas where ORiN can become an active solution is infinite. FA facilities apart, it is used for smart agriculture and smart medical care, for example.

In the future, ORiN will continue to expand its role in the world while augmenting its compatibility standards.

-

Factory ORiN supports the introduction of IoT and factory automation into manufacturing plants and connects a wide variety of machines used in various processes efficiently to increase productivity.

-

Medicine Various medical devices in an operation room are connected via a network. Information is collected from the devices and displayed on large screens in an integrated manner to assist the operators.

-

Farming Cultivation management systems are developed through collaboration between agriculture and industry. Cloud management is adopted not only for production but also for marketing activities to contribute to the exploration of new markets and the development of agriculture.

-

Development Applications can be developed more efficiently. ORiN makes it easier to establish systems, which helps shorten the development period and improve quality. It also supports the analysis of operation status and failure.